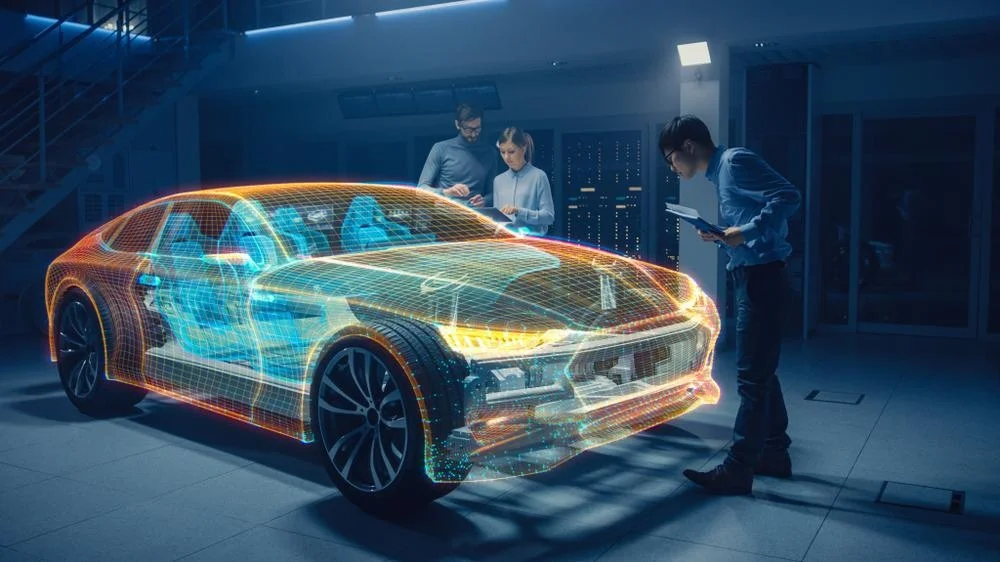

The automotive industry is in the midst of a technological transformation, and advanced ceramics are playing a pivotal role in shaping its future. With wunder-mold leading advancements in manufacturing, these materials, known for their exceptional properties, are being integrated into vehicles to enhance performance, improve efficiency, and ensure safety. With their unique combination of strength, heat resistance, and lightweight structure, advanced ceramics are proving to be indispensable in modern automotive design.

The Versatility of Advanced Ceramics in Automotive Applications

Advanced ceramics are engineered to withstand extreme conditions, making them an ideal choice for the automotive sector. Their applications range from improving engine efficiency to enhancing safety features, showcasing their versatility and importance.

1. Enhancing Engine Efficiency

Engines are the heart of every vehicle, and advanced ceramics are making them more efficient and durable.

Key Benefits of Ceramics in Engine Components:

- Heat Resistance: Ceramics can endure extremely high temperatures, allowing engines to operate at optimal efficiency without the risk of material failure.

- Wear Resistance: Components made from ceramics experience less wear and tear, increasing their lifespan and reducing maintenance costs.

Applications in Engines:

- Ceramic Coatings: Used on piston heads and cylinder liners to reduce friction and thermal loss.

- Turbochargers: Ceramic blades are lightweight and resistant to heat, improving the turbocharger’s responsiveness and efficiency.

Fun Fact: Did you know that ceramic coatings in racing car engines can withstand temperatures exceeding 1,200°C (2,192°F)? This makes them a favorite in motorsports for achieving high performance.

2. Advancing Electric Vehicle (EV) Technology

As the world transitions to electric vehicles, advanced ceramics are becoming a cornerstone of this eco-friendly revolution.

Why Ceramics are Essential for EVs:

- High Electrical Insulation: Ceramics are excellent insulators, making them crucial for safely managing the high voltages in EVs.

- Thermal Management: They help dissipate heat in battery packs and electronic control units, ensuring consistent performance.

Key Applications in EVs:

- Battery Systems: Ceramic separators between battery cells prevent short circuits and improve safety.

- Power Electronics: Ceramic substrates in inverters and chargers ensure efficient energy transfer and cooling.

Fun Fact: The first hybrid car prototype, developed in the late 19th century, could only dream of materials like advanced ceramics, which now enable modern EVs to run more safely and efficiently!

3. Improving Safety Systems

Safety is a top priority in automotive design, and advanced ceramics are making vehicles safer than ever before.

How Ceramics Enhance Safety:

- Impact Resistance: Ceramics are used in protective materials that can absorb high levels of force during collisions.

- Precision and Reliability: Ceramic sensors provide accurate data for airbags and braking systems.

Applications in Safety Features:

- Brake Pads: Ceramic brake pads offer superior stopping power and minimal wear, even under extreme conditions.

- Airbag Sensors: Piezoelectric ceramics detect changes in pressure or movement, triggering airbags at the right moment.

Fun Fact: Some high-end sports cars use ceramic brake systems that can last up to 70,000 miles without needing replacement, even under demanding driving conditions.

Why Advanced Ceramics Are Here to Stay

Advanced ceramics are not just a fleeting innovation; they are becoming a staple in automotive engineering. Their unique combination of lightweight structure, durability, and thermal resistance aligns perfectly with the industry’s goals of sustainability, performance, and safety.

Additional Benefits of Advanced Ceramics:

- Reduced carbon emissions due to improved engine efficiency.

- Longer-lasting components, lowering the total cost of ownership.

- Enhanced vehicle designs with fewer trade-offs between weight and strength.

The Future of Ceramics in Automobiles

As automotive technology continues to evolve, the role of advanced ceramics is set to expand even further. With the rise of autonomous vehicles and the growing adoption of hydrogen fuel cells, ceramics will likely play a critical role in enabling these breakthroughs.

Fun Fact: By 2030, the global advanced ceramics market is projected to reach over $15 billion, with the automotive industry being one of the key contributors to this growth.

Advanced ceramics are proving that innovation doesn’t always come from new technologies—it often comes from making better use of the materials we already have. By incorporating these remarkable materials, the automotive industry is driving into a future where vehicles are more efficient, safer, and environmentally friendly than ever before.

Also Read: Transforming Your Pool: Can You Change Its Shape.